Ball Valves are used to control the flow of the water or any other liquid. The industry has various demands according to the pressure that is having. For case, some of the industries that are dealing with high pressure of water will need the standard quality materials whereas there will be some industries where the amount of the flow will matter.

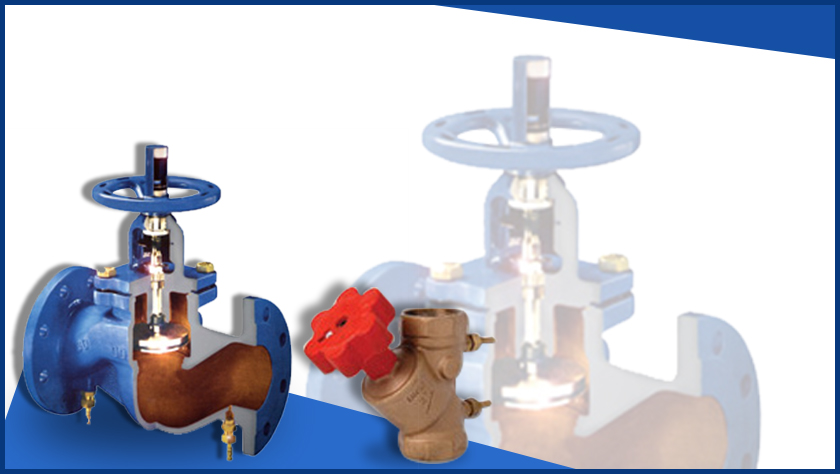

SKG Pneumatics Inc has been dealing all the type of valves such as Gate valves, Globe Valves, Ball Valve with strainers, Check Valves & Non-return Valve, Gate & sluice valve, Pressure Reducing Valve, Shutoff valves.

There are different types of Ball Valves available in our store. All of these valves used in Plumbing are built with the standard raw material to maintain durability.

Get quality of Ball Valves from leading ball valve supplier

There are many types of valves that are used in the industries. We provide all the valves that you need for all the industries. All the valves are built with great raw materials and the quality to ensure the durability of the product. Along with all of these, we also know about the budget of our customers and hence all the valves are affordable to buy for any of the customers. Here we as ball valve supplier offer different types of valves-

• Split-Body Ball Valve: Here the body is divided into two different parts and the cover along with the ball, seat rings are present.

• Top-Entry Ball Valve: They are available in various size and used by the people who are looking for having a single-piece body with the top entry.

• End-Entry Ball Valve: In this product, the ball is inserted at one end and is retained from other. These are the most affordable valves and are also available in large size.

• Three-Piece — Body Ball Valve: Her body is divided into the 3 parts where one main part is for holding the internals and the stem is released from the top where a hole is given.

• Double Trunnion Ball Valves: The ball is added with the two other integral shaft extensions. These are called the bottom and top trunnions. These are made to hold and for the shaft to rotate freely. A top shaft is used to open and close.

Also, if any of the valves have any variation, we also provide them. All of these are easy to install and will last for a long duration of time. You can use any of these for each and every need.

FSC

FSC