Industrial products are made up of manufacturing materials and plants, machinery and any other component or goods used by other firms or industries. Industrial designers can make innovative designs that are functional and affordable. Using quality industrial products, they can explore the design concepts. The manufacturer and supplier of industrial products play an important role in the innovation of new products. The feature and application of some essential industrial products are given below.

Our products –

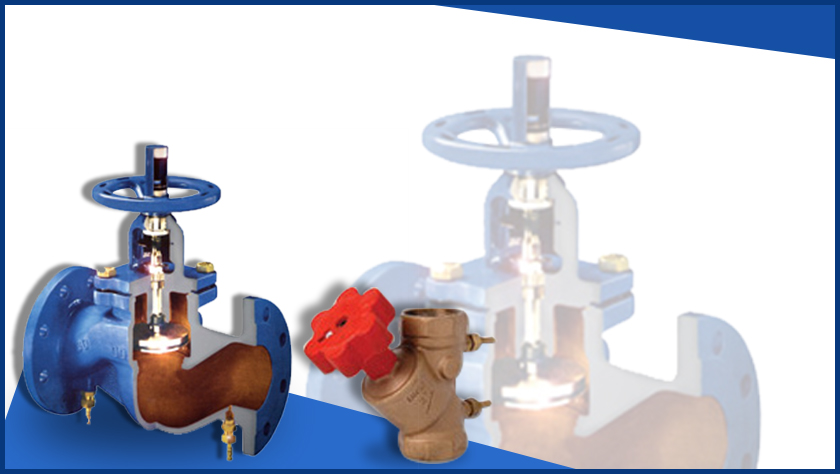

1. Pressure Reducing Valve –

The Pressure Reducing Valve (prv) is used to protect life, property, and environment. It acts as a safety device. It helps to control pressure within the pipeline. It is used in water supply, construction industry, sugar industry, sewage applications and oil and petroleum industry. These valves are durable, suitable for water, easy to install and suitable for air.

2. Balancing Valve (Flanged) –

Balancing Valves help to convert an inconsistent input pressure from a system into a consistent output pressure for another system. It is mainly used in Boilers and heat exchanger. These valves are tamper-proof setting including lock-shield and hand-wheel and précised with double regulation. It involves low flow-noise emission and positive shut-off. These valves are available with or without Drain Cocks and Pressure Test Cocks. The procedure of installation and operation of this valve are easy and simple.

3. Hydrant Valve & Landing Valve

Hydrant Valves are fitted on the post of hydrant stands. Landing Valves are used for firefighting offered on the riser in buildings. Landing valves are mainly placed typically in staircase landing for firefighters to access easily. Landing valves are an important part of a hose system for firefighting. Hydrant Valve & Landing Valve both are the same type of valve used for firefighting.

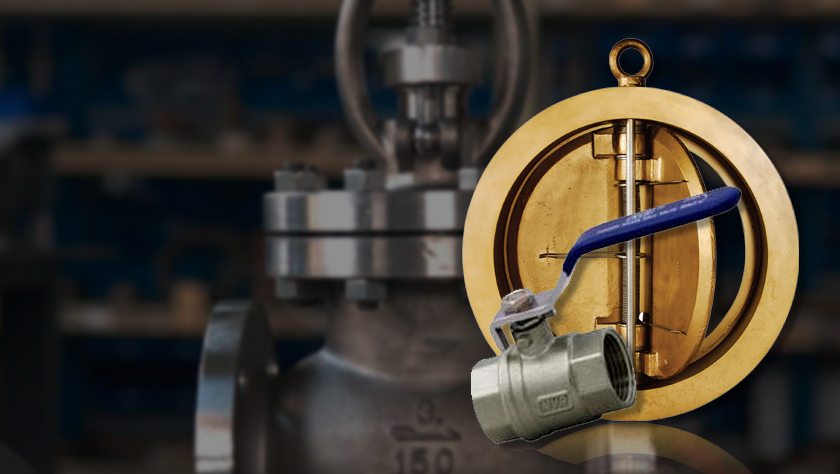

4. Ball Valves –

Throttle Valves or Ball Valves are used in water tanks, steam boiler etc. These valves help to lock on water and air easily. These valves are small-sized, less weight, easy to control torque and pressure. Ball valve with strainer is made up of rustproof stainless steel perforated sheet including strainer.

5. Strainers –

The strainer plays an important role in maintaining fluid circulation through pump consistently. It prevents clogging of nozzles and provides optimal operation of the sprayer.

We at SKG PNEUMATICS INC have a wide range of industrial products that caters to fulfil the needs of various industries. We always try to keep our product standards for satisfying your requirements and safety. We are an efficient supplier of industrial products which are available in various makes like Betaflo, Advance, NVR, Zoloto, Easy-flex, and New Age Fire Fighting Equipment.

FSC

FSC