SKG PNEUMATICS INC is one of the leading trader & dealers of all kinds of industrial products. We have a complete range of balancing valves according to their size, pressure ratings, operating temperature, and fluid characters including on-site commissioning for optimum performance.

What is Balancing Valve?

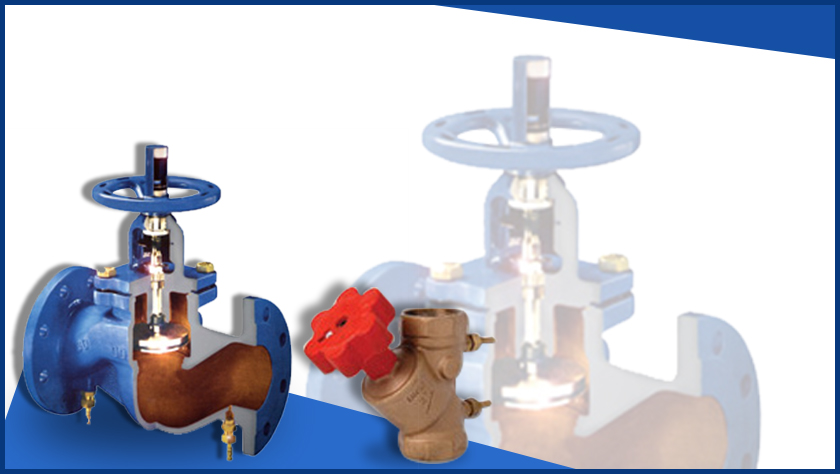

The valves that are used in the central heating and cooling systems based on the flow of the water are termed as Balancing Valves. Balancing is a practical technique for setting systems to meet design requirements. It helps overcome a wide range of system conditions where pipe sizing and pipe configurations alone cannot set a system in balance. The latest flow technology is used by these valves and they also ensure that if there is no change in the pressure within the system then the design flow rate of the system will be achieved at all times. The rate of the design flow is determined by the velocity of the water flow in the tube of the coils. The minimum flow is 1.5 ft / s (0.46 m / s) and the maximum flow is 12 ft / s (3.7 m / s).

We have a range of Balancing Valves from Advance Valves

Advance Valves provides a complete spectrum of valve metallurgy and services in the products. It is a leading company since 1986 and has its position among the top 5 quality manufacturers internationally in the product range.

Main features of the Advance Valves are:

- High-quality valves of exotic metallurgies made up of nickel alloys and titanium.

- Variety of sizes from 50 mm to 3000 mm.

- Valves up to ANSI #2500, and API 6A are available.

- Meet the requirement of the client.

- Valves for Cryogenic applications down to -196 deg. C are available.

- Valves for Fire safe application are made up to 550 deg C

- Valves complying with Fugitive Emission norms are manufactured.

- For Fire-water services UL certified valves are supplied.

- Excellent track record.

Balancing Valves – Screwed

When the system is unbalanced, water takes the easiest path through the system where the resistance is lowest and as per the result of the terminal units, radiators, fan coils, air handling units, chilled beams and radiant panels that are closest to the pump are provided with excess water flow. Units that are further away from the pump, seek insufficient flow. When balancing a system, flow distribution is changed so that critical circuits can be provided with the required flow. When the system is balanced, water flow can be set to design the requirements of all parts of the circuits. This results in good thermal comfort and no unnecessary energy consumption. Screwed balancing valves are the efficient operation of control devices to achieve energy savings, Room temperatures will be optimized throughout the building and lower fuel bills for the building occupier.

Balancing valves – Flanged

Flanged balancing valves help ensure that all components in a hydronic system achieve the required design flow. These valves are more accurate than screwed Balancing valves. The effect on the selection of the control by the flow system was not initially realized but flanged balancing valves are very effective for this purpose.

Applications of the balancing valves

There are numerous applications of the balancing valves. They are mostly used in boilers and HVAC chiller system to regulate the flow of liquids such as water. Creating a consistent output pressure to a system from an inconsistent input pressure from another system is the main purpose of the balancing valves. Balancing valves are also used as the heat exchangers for ensuring the optimum flow of the liquid throughout the system.

SKG PNEUMATICS INC is of the leading balancing valves manufacturers and distributor with a wide list of happy customers all around the world. It is a highly rated company which supplies balancing valves and all kinds of advance valves. It is one of the best Advance valves dealers and balancing valves suppliers around the globe. Customer satisfaction is the main motive of our company. If you are also interested in buying these valves then it will be our pleasure to provide service to you.

FSC

FSC