A strainer is an essential part of a piping system. It resists dirt and foreign particles carried by the process fluid. As a result of this, a strainer protects equipment from being damaged. Strainers can be placed upstream of the pumps to resist the construction debris left within the pipe. You can install permanent strainers upstream of the traps, control valve, and instruments to withstand the corrosion element, which may become dislodged and carried within the piping system. You can choose the Advance Valve dealers in Delhi for the right types of strainers.

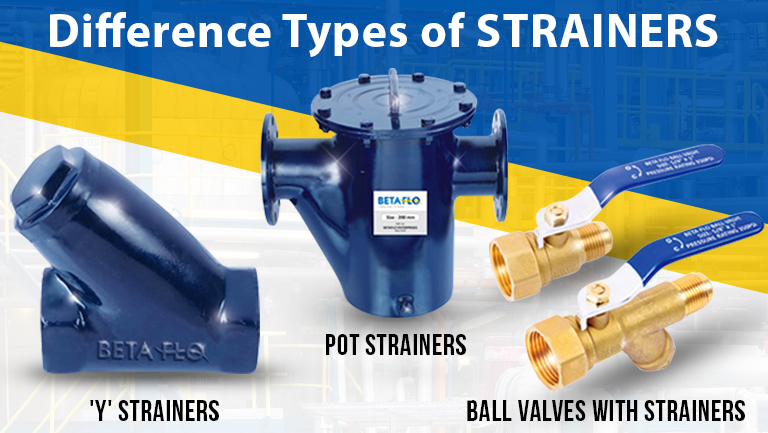

Difference Types of STRAINERS are:-

Y-Type of strainer helps for the removal of the foreign bodies present within the pipeline. It protects pumps, valves, meters, and similar types of equipment. Y-Type of strainers are usually used for the coarse filtration. Fine mesh is also used for the large filtration area. It helps to improve the clearance of the medium. Y-Type of strainers are suitable for gas, water, steam, petroleum, and other fluids. It is ideal for the installation horizontally and vertically positions with the screen element pointing downward. The Industrial Valve Dealers in India for producing different types of valves and strainers.

Pot strainers help to remove foreign particles sized in a 0.001-inch diameter from different types of flowing fluids. It allows for the removal of dirt and also unwanted materials within the fluid. Sometimes, it removes valuable products. The pot strainer is also known as a basket strainer. Pot strainers are generally installed horizontally. It is suitable for high flow service. The pot strainers are available in duplex style. The base of the pot strainers needs to be supported.

The ball valve with a Y-Type strainer is made up of brass. Generally, the ball valve controls the flow of the fluid positioning through a ball. The ball is made up of forged brass chrome-plated. The handle is made up of steel chrome-plated. Gland nut and bonnet are made up of forged brass. You can select one of the best valve suppliers in India to purchase the ball valve with a strainer.

FSC

FSC