Butterfly valve is typically used for the regulation of fluid flow. It is most widely used for supply of water for fire protection, for industries related to fuel and chemical along with various other applications. Unlike the ball valves, butterfly valves actually operate with single quarter-turn mechanism. There are various types of butterfly valves which can be found in the market today.

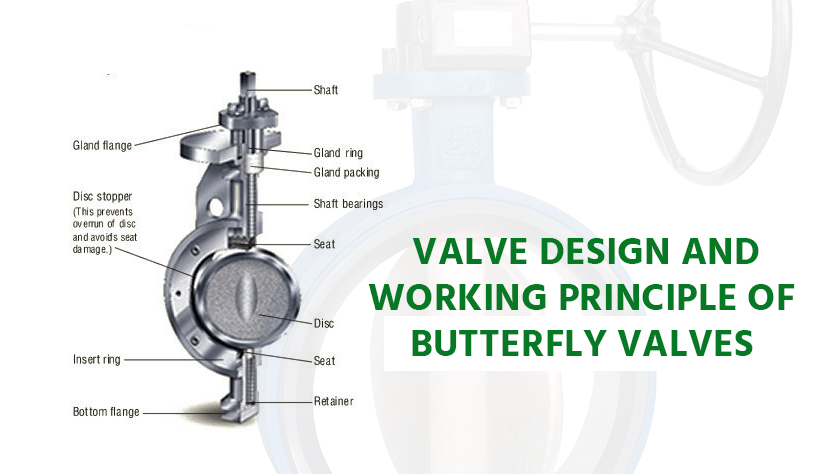

Butterfly valve is basically based on the principle of quick shut off. It functions with a disc in the center pipe which permits a small rod to pass through it to the actuator which is present on the external side of the valve. The valve allows the flow of fluid when the user rotates the disc with a quarter turn. It is also known as the quarter-turn valve. The valve gets its name from the metal disc attached to the rod which helps in permitting the flow of fluid with a quarter turn and also helps in blocking the passage. This disc, which is often called as the butterfly is the most part of this form of valve.

The best butterfly valve that you can use depends on your purpose of using the valve. It has gained quick popularity in the industry due to its easy to start, stop and regulating feature.

You can get four different types of butterfly valves in the market.

-

Motorized Butterfly Valve:

This type of valve is used widely for controlling the flow of fluid via a pipeline. It operates by simply altering the position of the round disc which is present with a system pipeline. You can use this type of valve for pipeline o any size as they are available in various sizes and specifications which you can choose according to your need.

-

Concentric Butterfly Valve:

This type of valve is used for the regulation of low-pressure pipelines. This can be installed very easily and will also provide with the 100% efficiency. This type of valve is the lightest of all.

-

Wafer-Type Butterfly Valve:

It is very easy to use type of valve but it fails to function as the valve for isolation.

-

Pre-insulated Butterfly Valve:

This type of valve is the most durable out of all and are resistant to cracks.

If you are looking out for suppliers of industrial valves, SKG Pneumatics is the one which you should opt for. It is like a one-stop-shop for all your industrial needs.

FSC

FSC