The balancing valves are used to achieve hydraulic balance during the commissioning cooling and heating system. The balancing of the heating and cooling system is maintained to ensure that the right amount of water is present at every point of consumption. Balancing valves create adjustable resistance within the system. You can choose one of the best Advance Valves Dealers in Delhi for purchasing balancing g valves.

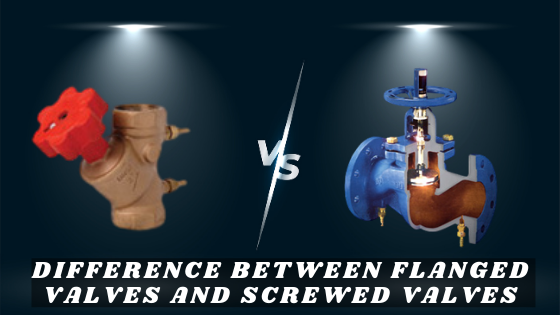

Balancing valves – Flanged

The salient features of the balancing valve – flanged are as follows.

- Designed with the standard BS 7350

- Handwheel operated

- Precise double regulation

- Flanged ends to BS 4504 under the section of 3.2 PN 16

- Low noise flow

- Tamper-proof setting

- EPDM rubber sealing to create a soft shut off

- Available with or without drain cocks

Advance Valves Dealers in Delhi are renowned for quality balancing valves. The maximum temperature of the balancing valve – flanged is 110 degrees Celsius. The body, bonnet, handwheel, and end cap of the valve are made up of cast iron. Nut, washer, disc holder, and adjusting studs are made up of carbon steel. Stem, gland, and sleeve nut are made up of stainless steel. The plug is made up of bronze.

Balancing valve – Screwed

The salient features of balancing valve – screwed are as follows.

- Designed with the standard BS 7350

- Handwheel operated

- Precise double regulation

- Available PTFE sealing disc to ensure a perfect shut up

- Easy to install and set

- Tamper-proof setting with a lockshield

- Provided with inlet or outlet pressure test corks

- Save energy

- Accentuates systematic commissioning of the systemto get an optimal operation

You can depend on Advance Valves Dealers in Delhi to purchase the right balancing valves. The maximum temperature of the balancing valve – screwed is 220 degrees Celsius. The body, disc holder, and bonnet are made up of bronze. The nut, upper stem, and lock pin are made up of brass. The washer, lower stem, lock nut, plug, and gland nut are made up of bronze or brass. The disc is made up of PTFE.

The information mentioned above will help you to choose the right types of balancing valves. You can select one of the best Advance Valves Dealers in Delhi to get different options for balancing valves as per your need.

FSC

FSC