Both check valves and non-return valves serve the same purpose, i.e., prevent the fluid from flowing back. Though they serve the same purpose, they are not the same. Let’s have a look at both of them in-depth.

Check valves

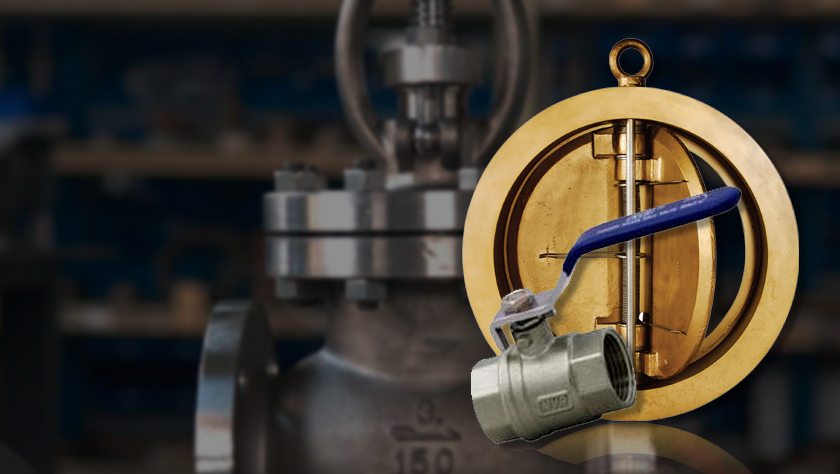

A check valve is a mechanical device used in hydraulic systems to stop the flow of the fluid in one direction and allow free flow in the opposite direction. Unlike other valves, check valves do not require assistance to open and close. They even work if the plant loses electricity or air. Most common types of check valves are:

-

Swing type

-

- Top hinged

- Tilting disk

-

Lift type

- Piston type

- Ball-type

-

Dual Plate type

-

Stop Check valve

Non-return valves

A non-return valve is a mechanical device that is used to ensure that the fluid flows in the right direction, where pressure conditions might reverse the flow. Non-return valves are usually operated manually. Most common types of non-return valves are:

- Spring-loaded non-return valves

- Clapper type non-return valves

Difference b/w check valve & non-return valves

While many manufacturers consider check valves and non-return valves as the same thing, it is not actually the same. Check valves prevent backflow in defined circumstances, and it has to meet very strict criteria to ensure fluids are not able to siphon back into the systems. Whereas non-return valves need not meet the strict guidelines as check valves.

Applications of check valve & non-return valves

Check valves and non-return valves are most commonly used in hydraulic systems and pumping stations. Other applications include:

- Wastewater management

- Portable water management

- Irrigation

- Mining

- Food and beverage

- Oil and gas

- Pharmaceutical

- Power plant

Both check valves and non-return valves help:

- Protect equipment downstream from backflow damage

- Prevent contamination due to reverse flow

- Prevent siphoning

- Keep a vacuum seal

SKG Pneumatics INC is the leading industrial valve suppliers in India. No matter how big or small your requirement is, we can fulfill your order instantly. Explore our range of products to find what you are looking for.

FSC

FSC