Strainers come in a range of shapes and sizes, with their names planned in agreement with their structures. They are typically made of aluminum and copper which build them fitting for use with stream and make them oxidization resistant. The most usually used filter is Y & Pot strainers. Pot filter is as well called basket filters. SKG Pneumatics Inc. is known as Beta Flo Valves Dealers in Delhi

Below are the purposes of filter based on their types:

- Y Strainers

- Pot Strainers

Y Strainers

The most normally used kind of filter. As its name proposes, it has a Y-shaped corpse, which ensures that it offers low resistance to fluid way and guide to a low-pressure defeat. This makes Y-strainers appropriate for submission where the amount of solid subdivision to be worried is less. These funds it is less vulnerable to being unclean and requires fewer cleaning. Hence it is used under pressure pipelines, vapor, liquid or gas, blankness or suction state.

Pot Strainers Beta Flo Valves Dealers in Delhi

Its design makes sure that no disturbance occurs in the organization while cleaning the filter by changing the flow of the liquid to a second filter during the clear-out process. A structure is in place to notice when the initial pot or container is full, so the flow is transmitted to the second filter and free the first seal for clear out by the worker. Pot or container filter is used for applications concerning strong chemical response and abrasives.

A few strainers come close with the ball control device. Ball valves are quarter-turn control devices, extremely powerful and durable which at times makes them other desirable than ball or gateway valves. But, it is able to only be used for the on-off purpose, and lack the authoritarian facility other valves. Ball valve with filter is more helpful in fact, for its stream control behavior with a particulate ensures. As suppliers of the filter and developed valves, we at SKG plan to get the best excellence standard goods to market, from the excellent designers

Orientation Y-type Strainer

A Y-strainer can be set up in either a flat or vertical position downflow with the monitor element end downward. This permits the strainer display to collect substance in the strainer at the lesser point of the monitor. In horizontal condensation or gas tube, Y type filter should be set up in such a method so that the compartment is in the flat plane. This stops stream from gather in the pocket which can foundation erosion and involve heat transport processes.

In water systems, the compact should position up and down downwards. This makes sure that the unconcerned debris is not strained back into the upstream pipeline work through a low flow setting. Although it is sensible to set up strainers in flat lines, this is not all the time likely, and they can be set up in straight-up pipelines if the flow is downwards, in which casing the remains is naturally aimed at into the compact.

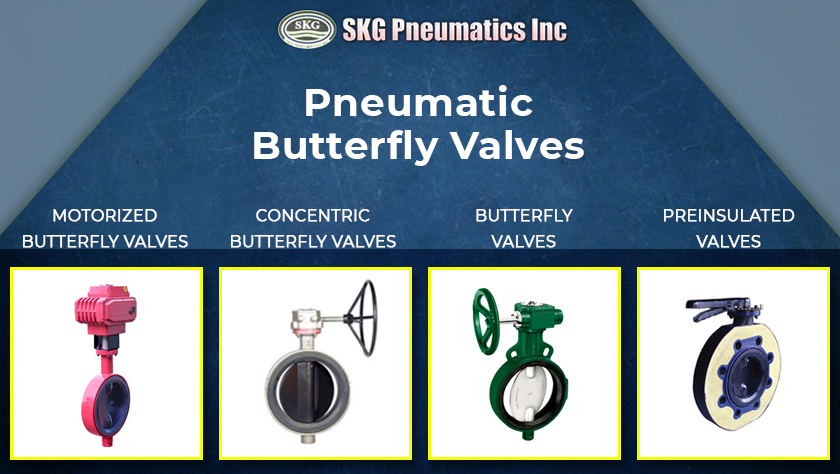

Butterfly valves Beta Flo Valves Dealers in Delhi

VTM Butterfly Valves are perfect for bi-directional blind alley service in profitable, industrial and hydronic processes. VTM provide a wide variety of Butterfly control device in Iron, harden, Stainless harden, Aluminum icon and foreign alloys in concentric or huge performance devise construction. The choice of wafer, flanged or uneven ends are accessible. Use VTM range guides and submittal support to make your range easier and more specific.

Strainers find utilize as filters in extrication solid particles from fluid smooth through an organization or a pipeline. They can vicious circle debris and dust in a liquid which builds them very functional in examines scenarios. Check out SKG Pneumatics Inc. which is known as Beta Flo Valves Dealers in Delhi

FSC

FSC